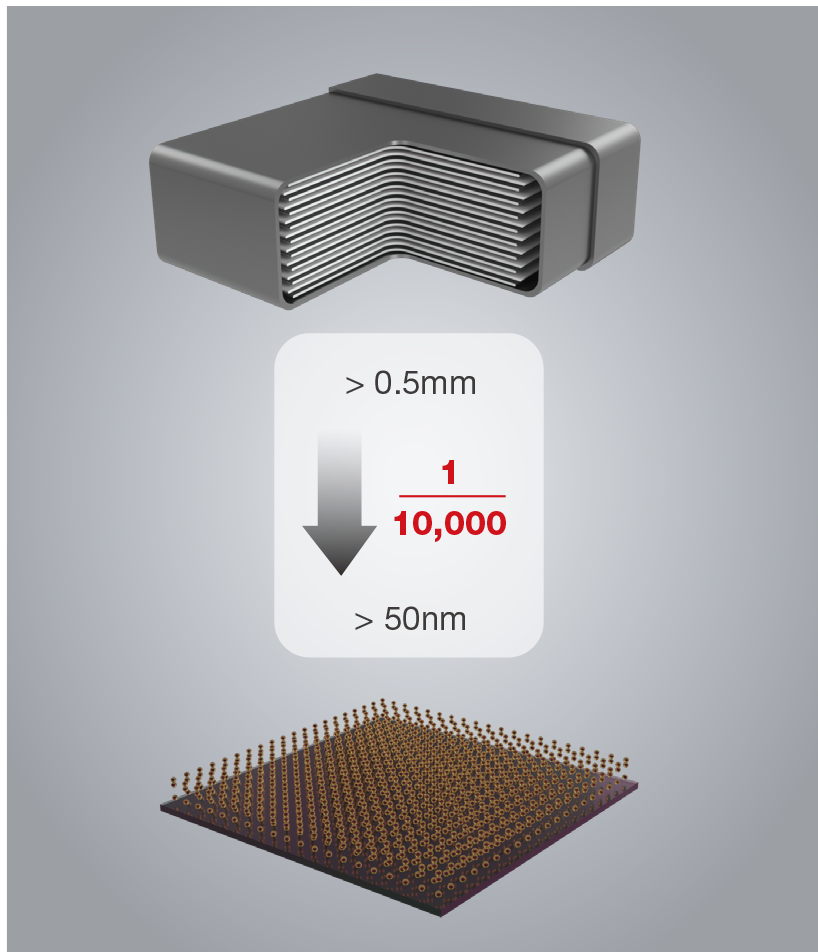

| Bulk Type | vs | Thin Film Type |

| cm or mm | Unit size | nm (<1/10000) |

| 15 steps | Process step | 4 steps |

| ~ 1 month | Process time(1set) | ~ 6 hours |

| ⬆ | Production cost | ⬇ |

| O (Toluene, Benzene) |

Toxic materials | X |

Core Technologies

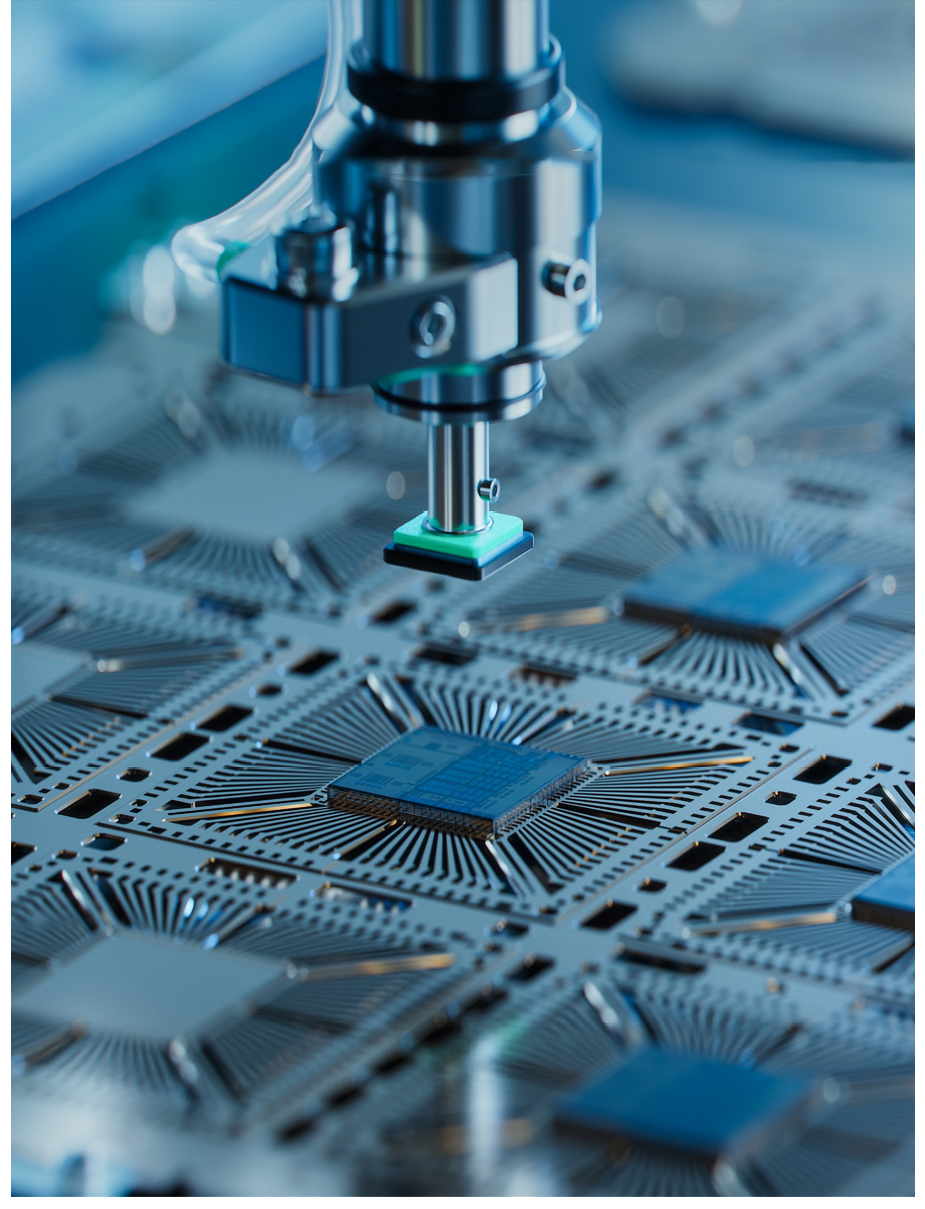

deposition process

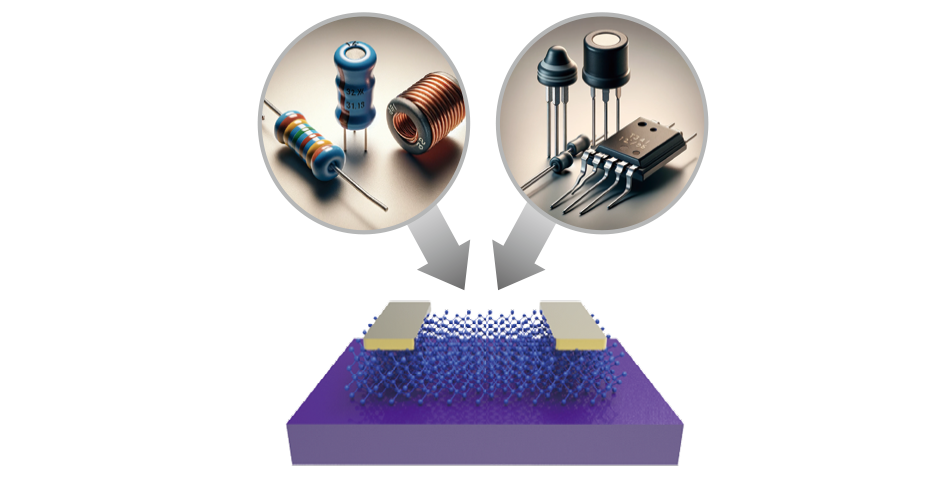

components

bulk to one chip

World 1st Multifunctional Energy Responsive Thin Film

Sensing + Switching function to Thermal or Electrical energy

Fabrication Process

Competitive Price

Function & Performance

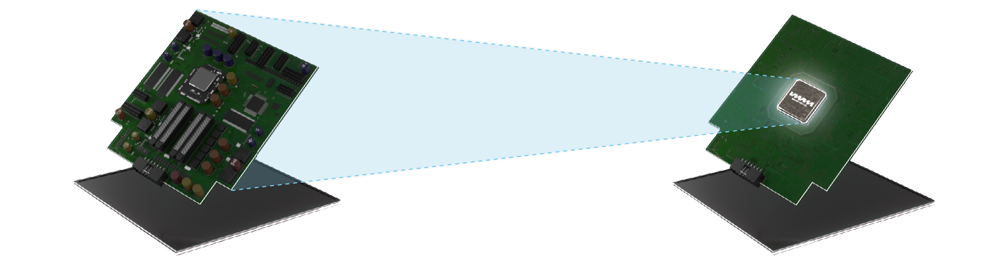

Increased accuracy through system simplification

Conventional System

Ultra Simplified System

“Next Generation Thin Film on Emerging Technology”

High-crystalline thin film deposition source technology

PoC in progress with R&D partners

Quantum Computing

A.I. Semiconductors

Power Electronics

Glass Substrate

Advanced Materials

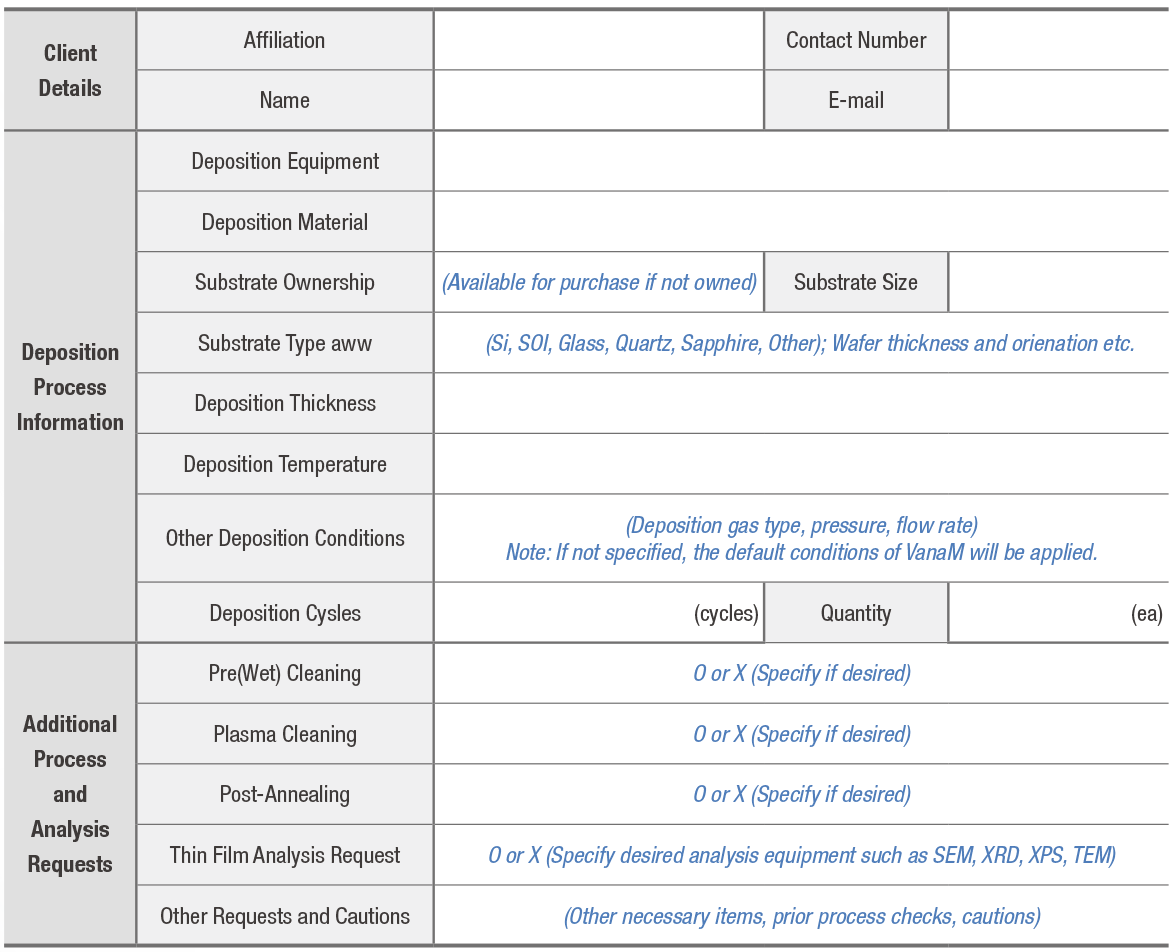

Customized Thin Film Deposition Service

to customer needs.

Development of special thin films & deposition process conditions

unavailable in conventional fabs.

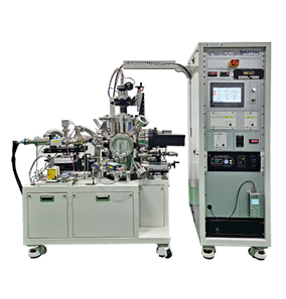

PVD–Sputter & Evaporator

Oxide VO2, V2O5, TiO2, Ta2O5, HfO2, ZnO, ITO, IGZO, …

Nitride TiN, AlN, AlScN, SiNx, …

Metal Au, Pt, Ag, Al, Ti, Cr, Ni, Bi, Mo, Hf, Sc, W

ALD

Oxide Al2O3, HfO2, ZrO2, HZO, ZnO, TiO2, In2O3,

Ga2O3, SnO2, SnO, …

Metal Pt, Ru

Deposition Process

Innovative R&D Service for Thin Film

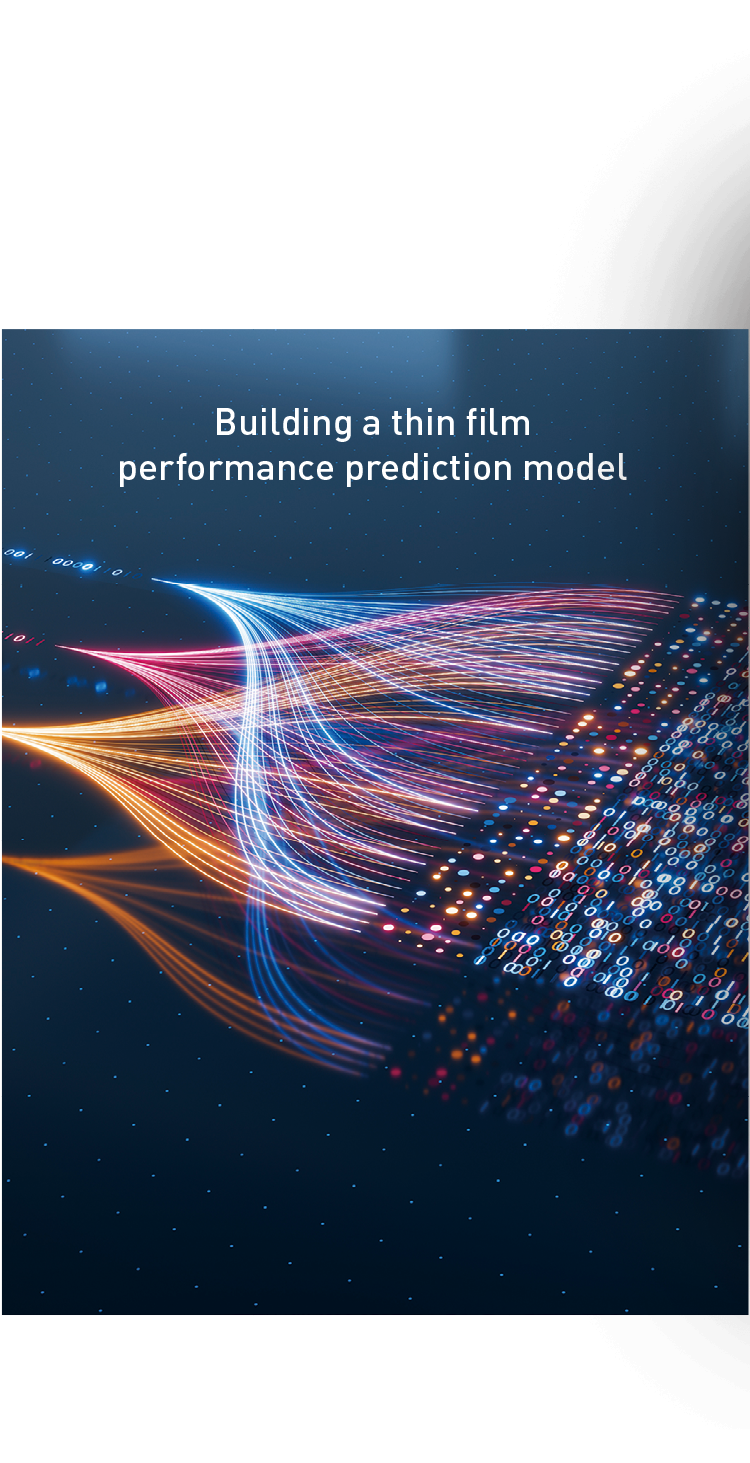

A.I. development of prediction model

customer request. It also collects and analyzes

data generated during the process to predict

the thin film’s characteristics, dramatically

reducing time and cost

• Desired thin film properties + optimized process

• Device design and Fab-linked device manufacturing service

customer-specific thin film & device analyses,

from non-destructive spectroscopy

to electrical analysis

SEM, TEM, XRD, XPS, UPS, AFM, Raman

• Device characteristic analysis

I-V, C-V, Pulse measurement, Ferro., Piezo.

new material thin film development

• Chemical energy potential calculations for thermodynamics and area selectivity

• Physical variables such as crystal orientation, morphology, and strain

Research Team

• Thin film materials and process technology analysis

• Thin film simulation

• Commercial viability test

Patent Team

• Core IP analysis based on technology verification

• IP portfolio construction

• Technology transfer mediation

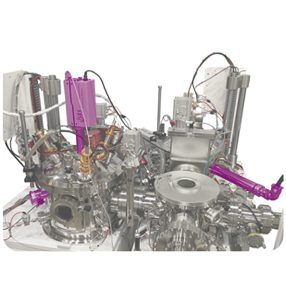

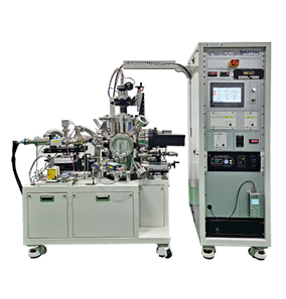

with a team of vacuum equipment

manufacturing experts with over

30 years of experience

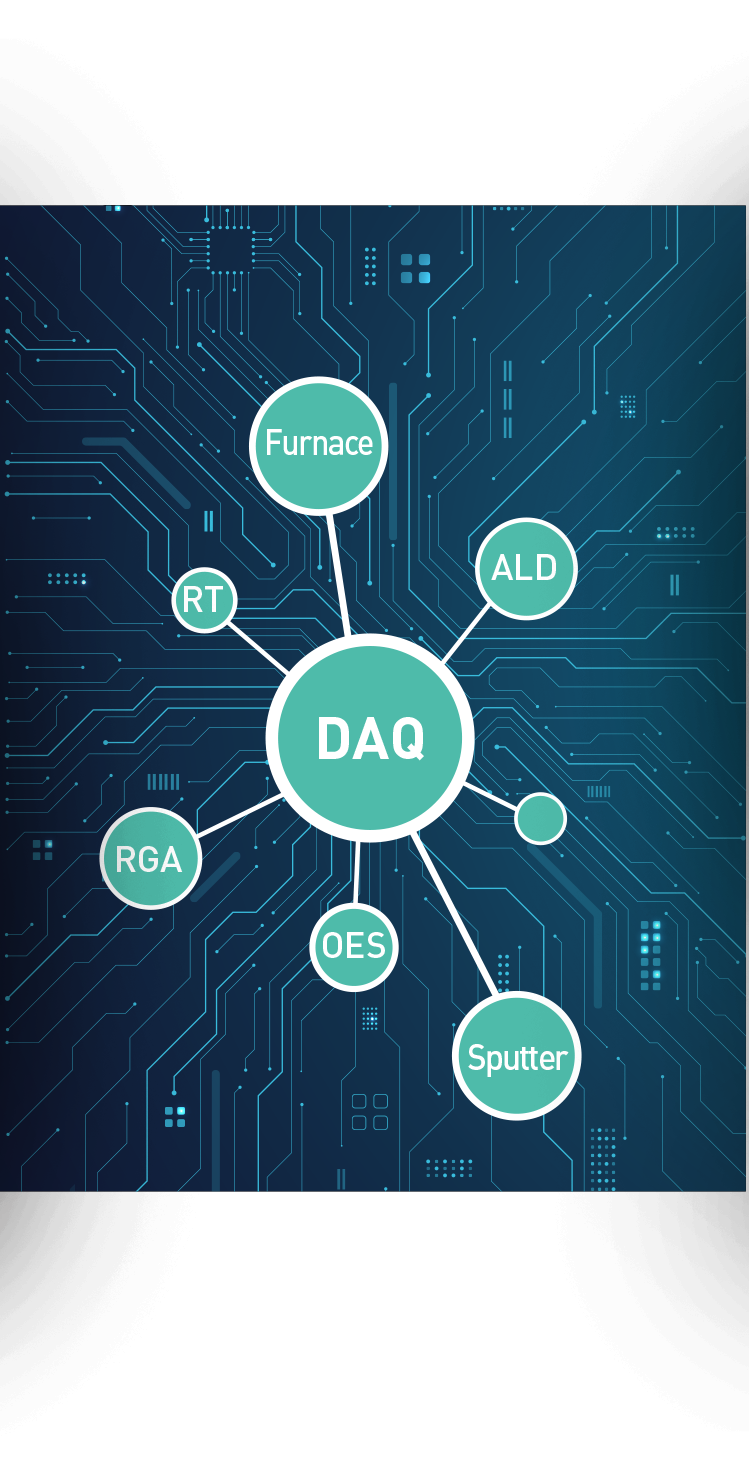

VanaM provides process technology and deposition solutions that go beyond simple manufacturing, thereby minimizing the cost and time incurred in the early R&D stages. We have developed special deposition instruments equipped with an additional system that can secure process data such as plasma wavelength and residual gas, enabling thin film performance prediction and process optimization through machine learning.

Sputter

PLD

Evaporator

ALD & MOCVD

Process Big Data Collection System

Sputter

PLD

Evaporator

ALD & MOCVD